Phonewell

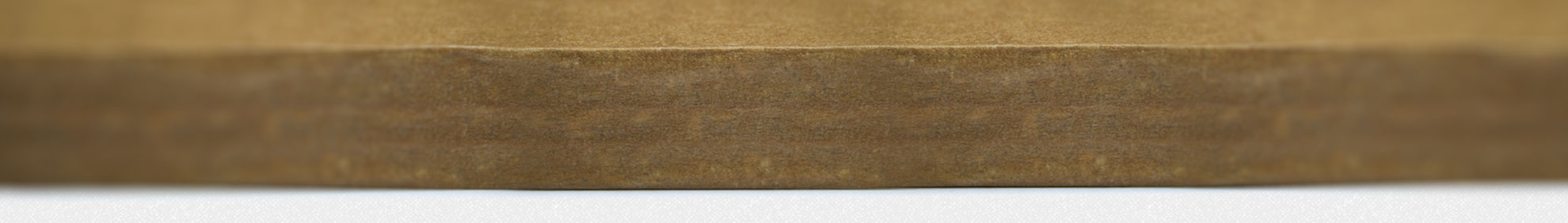

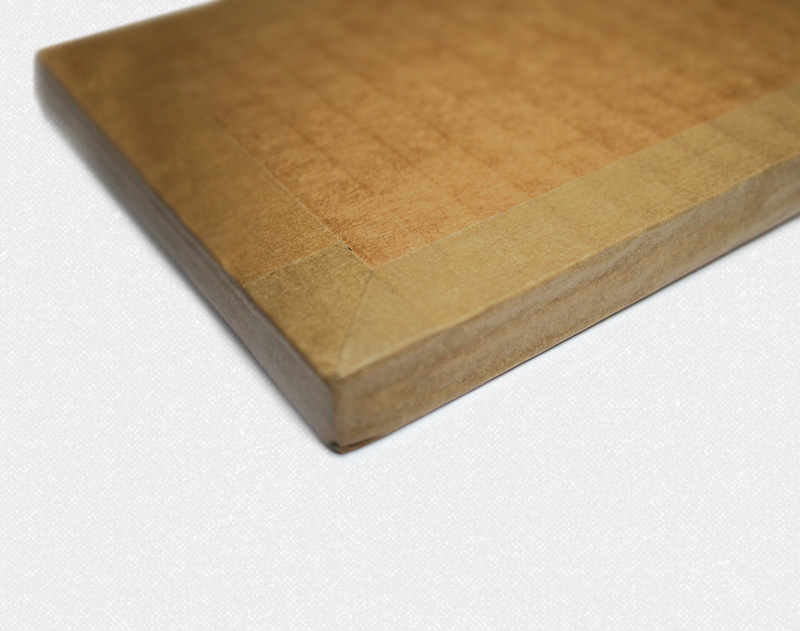

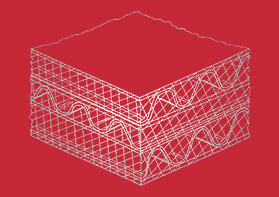

Phonewell is a footstep soundproofing panel (impact and airborne sound). Its cardboard structure consists of crossed and glued layers filled with pure burnt quartz sand and a heavy loose mass. Only a mass of this kind, combined with lightweight filler material, can ensure such high soundproofing properties. This patented combination is the key to unprecedented living comfort.

Use

Product suitable for installation on roofs, floors, walls and ceilings.

Benefits and Applications

Phonewell, insulation advantages:

• footstep sound damping

• soundproofing

• very high resistance to pressure (35 N/mm2)

• favours diffusion

• makes floors warmer

• biologically pure

• odorless

• provides environments that are suitable

for allergic individuals

• no hazardous substances used.a

Phonewell, installation benefits:

• only 15 mm or 10 mm thick

• fast to install

• does not require additional connecting elements

• immediately treadable

• no drying time required

• clean

• easy to process

Applications

Speed and low cost are the features of the installation of this kind of insulation.

Unlike conventional dry screeds, in fact, Phonewell does not require insulation strips along the edges, so installation becomes easy and much less expensive. Moreover, precisely because no screws or glue are required for installing the panels, acoustic bridges are no longer a problem.

Phonewell panels can be installed right against walls. This means that the loose filler material does not transmit sound waves.

When laying a traditional water-based screed, 2,000 to 2,500 litres of water are used for every 100 m2. Research has shown that it takes years for this water to evaporate completely, creating a source of risk to the building’s structure in the meantime.

Examples of installation

Simple and fast installation

Installation is truly fast and simple.

On floors: the installation of Phonewell panels only requires a staggered layout, starting from a corner of the room and proceeding with the remaining panels. On solid walls: only tile-glue is required to glue the panels onto the wall.

On wood structures, roofs, ceilings and walls: the panels are fastened using wood screws.

Processing

Cutting with a hacksaw:

Place the panels on two tables of equal height. Cut with the hacksaw.

Cutting with a cutter:

Place the panels on two tables of equal height. Cut with the cutter.

Sealing:

Close the cut edge with biological paper tape to prevent the filler from falling out. Always seal the cut edges with paper tape or general purpose single-sided tape.